Microwaves and megasounds for olive oil extraction

Recently, the research studies carried out on plants for the olive oil extraction were oriented on the introduction of innovative tools for the olive paste conditioning: microwave and megasonic systems able to condition the olive paste in very short time. Puglia (Italy) and Australia: two different situations, far apparently but linked by the intention to share their knowledge to improve the olive oil sector

Puglia and Australia: two different situations, far apparently but linked by the intention to share their knowledge to improve the olive oil sector. At the AGROLIO s.r.l., a mill placed in Andria (BT, Puglia – Italy), the first experimentation to evaluate the ability of microwave-megasonic combined system in an industrial olive oil process.

Recently, the research studies carried out on plants for the olive oil extraction were oriented on the introduction of innovative tools for the olive paste conditioning: microwave and megasonic systems able to condition the olive paste in very short time. The application of these new technologies could permit a definitive change in the olive oil extraction process, overcoming the actual limits of the malaxation operation. The malaxation consists of a slow mixing and heating of olive paste and is a unique discontinuous operation in the entire process.

To concretely test the new technology and its potential implementation to a real application, it had to be tested not only on a laboratory scale, but also implemented in a real industrial scale plant, to see its effects in a real scenario.

To address this necessity, the research groups of Dept. SAFE – University of Foggia, of Dept DISAAT – University of Bari and the EMITECH srl (Corato – BA) owner of a patent on the use of microwaves in food sector, developed the first “industrial modular plant based on microwaves” for the olive paste conditioning in continuous mode. A long session of industrial experimental test, since 2011’s, followed the design phase. The microwave system, in this way, has been improved and good results have been obtained. In particular, a reduction of conditioning time, a continuous and homogeneous olive paste heating and a strong simplification of the plant’s layout, were obtained.

These positive results have been obtained in the last year within a multinational collaboration between the University of Foggia, University of Bari, Republican University of Uruguay and the CSIRO (Commonwealth Scientific and Industrial Research Organisation). In CSIRO, Dr. Pablo Juliano and Dr. Xing-Qing Xu are studying, from many years ago, the application of megasonic sound waves for oil extraction from different vegetable matrices. CSIRO owns the industrial invention patent for vegetable oil extraction using megasonics. The constituted research group carried out joint research to evaluate the combination of the thermal and nonthermal effects, imparted by electromagnetic energy at 2.4 GHz (microwaves) and the acoustic waves in a frequency range of 400-600 kHz (megasonic) during the olive oil extraction.

The idea to combine these two technologies responds to a commercial need to extract the oil droplets from olives and to aggregate them in a liquid phase, in a continuous and efficient way. Therefore, the application of microwaves to the olive paste, containing the intracellular water, permits the heating of the paste because the interaction of electromagnetic energy with water. The megasonic application to the paste facilitates the separation of the oil phase from the solid phase. The technique is the “acoustic separation”, based on the generation of a standing wave field due to acoustic pressure; in these fields the oil droplets adhere one to the other, on the basis of their specific mass, promoting coalescence effects. Based on previous studies on both technologies and on the basis of laboratory test conducted together with the Australian team, the microwave and ultrasound technologies were evaluated in conjunction in the olive oil extraction process.

The benefits of combining both technologies was demonstrated in terms of (a) the possibility of facilitating a continuous process via the microwave technology, which avoids the batch malaxation process; (b) the additional oil recovery obtained from the microwave conditioned treated paste after megasonic treatment. Therefore, this international collaboration led to designing and developing, at an industrial scale, the first combined system constituted by two prototypes “microwaves- megasound”), for the continuous olive paste conditioning.

The two prototypes developed and constructed in Italy (microwave machine) and in Australia (megasonic machine), were installed in AGROLIO s.r.l., a mill placed in Andria (BT, Puglia – Italy), in a 2-phases extraction plant (MORI-TEM S.r.l.).

Several industrial trials were performed, using the technologies individually and in combination, while comparing to the traditional process. The use of microwaves alone confirmed the results obtained in past researches; the extraction yield resulted equal to that obtained using malaxation, reducing the processing time from 30 minutes to 1 minute.

The use of megasound, in addition to the malaxation or in combination with microwaves showed additional yield extraction in both cases.

No differences were registered in terms of free acidity, peroxide index and spectrophotometric indices. On the other hand, little differences were registered on aromas and phenolic compounds, considering the chemical analyses; these differences were not evident in the panel test. Moreover, the panel test excluded the presence of defects in all produced oils and revealed a good balance in positive aromatic notes (pungency, bitter and fruity). Currently, evaluations are underway on the on oils’ shelf-life.

The experiment was aimed to provide a result that was as close as possible to a real production scenario and able to give real guidance on the use of these new technological tools in the oil industry.

They were performed over 100 experimental tests and used more than 35 tons of crushed olives, devoting an entire oil campaign; a large use of resources, therefore, paid off by the excellent results in terms of flexibility and system operation.

Finally, the tested technologies have demonstrated their potential for the efficient and continuous extraction of oil from olives, having an excellent quality. The continuation of the research and a partnership between Italian and Australian research teams is being developed for further improvement of the current techniques industrially tested.

Acknowledgements

This study was funded in part by Puglia Region “Guidelines for Research and Experimentation in Agriculture 2012-2014”, MICROLIO research project and by the CSIRO Julius Career Award grant. The authors are most grateful to the AGROLIO MILL s.r.l. and to the owner, Mr. Savino Agresti for providing their facility to carry out this work.

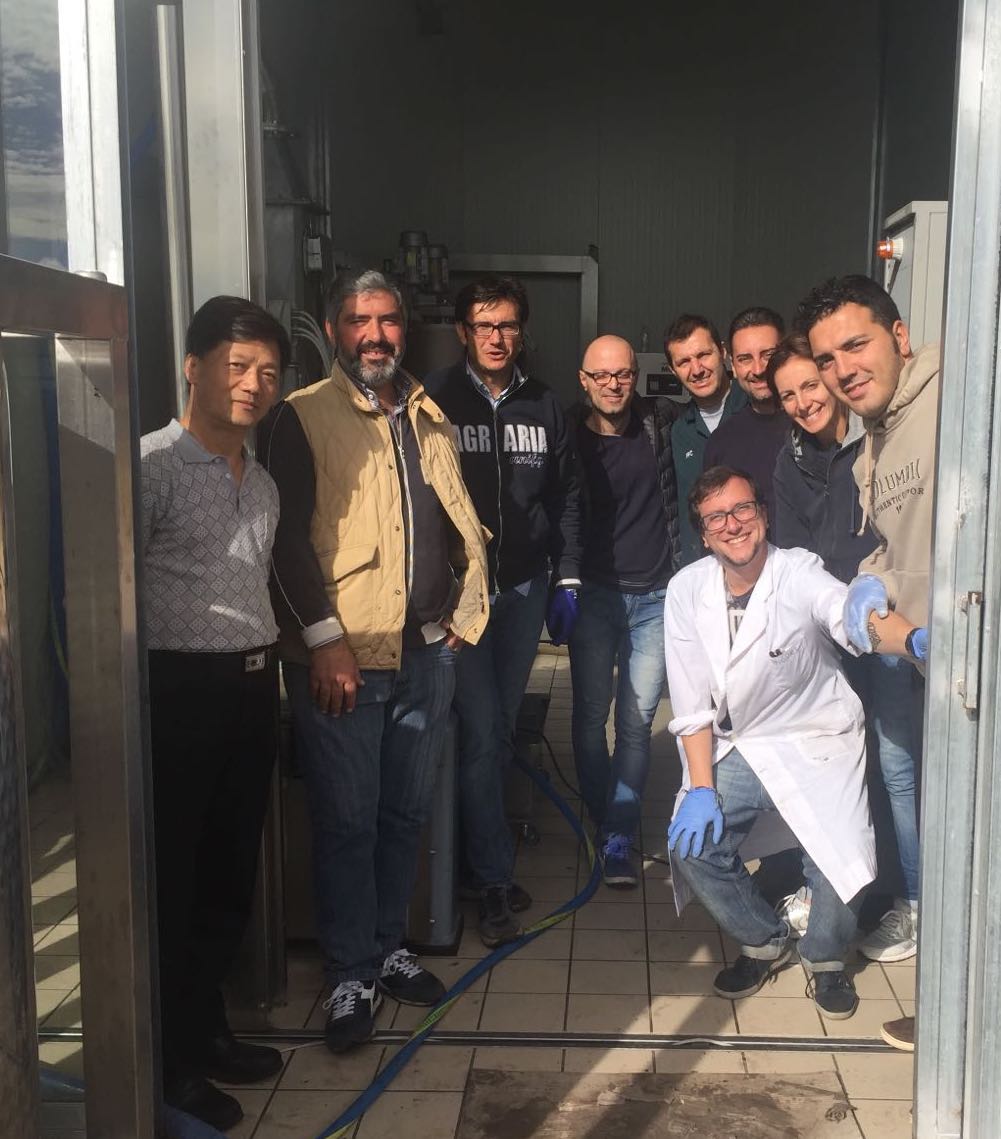

Research team in the Agrolio mill:

from top left: Xin-Qinq Xu, Savino Agresti (Agrolio’s owner), Alessandro Leone, Michele Diaferia (Emitech srl), Pablo Juliano, Roberto Romaniello, Antonia Tamborrino, Domenico Tarantino (University of Bari)

down: Miguel Amarillo

To comment you have to register

If you're already registered you can click here to access your account

or click here to create a new account

Comment this news